The Future is now: Our Digital Printing Process on Porcelain

The Digital printing process on porcelain has evolved from unreliable and inconsistent, to the new age of decorating porcelain.

Millions of colors are now available to print when previously only few were possible. A larger gamut range also comes with the bonus of high quality print (up to 1200 dpi).

Screen Printing & Dye Sublimation We Are Not

Previously and still to this day we were printing porcelain and ceramic with screen printing or dye sublimation. Both have their limitations, we think the most limited that although looks bright and with high definition but despite looking good, easily wears off and scratches off - and that is dye sublimation. There is absolutely no protection and no glazing so the image either scratches off or within a short time fades away.

Video On Us vs Them (short video)

Watch this short video on how we can scratch off dye sublimation tiles.

Screen printing on the other hand has been around for like a thousand years. Often plates you would purchase at a large store that has a design or flower on them have been screen printed and then they glaze over it. The difficulty with screen printing is that you have to do lots of them and make screens for every application. They also are NOT full color/colour they are "spot color" and low resolution. More durable than dye sublimation but not practical unless your order is like a box store around the world requires.

What About Us At Paris Group?

Now enter Paris Group Inc. Porcelain and Ceramic Printers...ta da! Okay, enough of the fan fare but our process the digital printing process, blends those two worlds together but does not use any of those two systems to do what we do.

We have the full high resolution and we have all the colors and have no minimum order and its glazed so its extremely durable.

See more of our pictured wall tile here and printed floor tile (those other guys, can't do this)

And we were experimenting on printing bathroom sinks over the last few years - and voila! We now can do that too! Custom Printed Bathroom Sinks

Also all kinds of dishware that is dishwasher and microwave safe see plates and vases and platters and bowls www.PhotoPlates.net also nobody prints inside mugs like we do check out our amazing printed mugs with print on the inside and handle www.PrintINmugs.com

This was our Trade Show Booth in the Franchise Show in Toronto. These are 12 x 12 inch Porcelain Floor Tile. So this printed floor mural is 2 feet by 3 feet for a total of 6 square feet.

We took this image and put an active QR code on the floor tile as well, so you can walk by the booth, maybe when we weren't there or were talking with other customers and take your phone and get to our website.

Any image you get or create we can print and make it durable and useable.

Folks were walking on this floor tile all day long at our Franchise show.

This is not a "franchise opportunity" but because its a very unique opportunity and its a business opportunity they wanted us at the show.

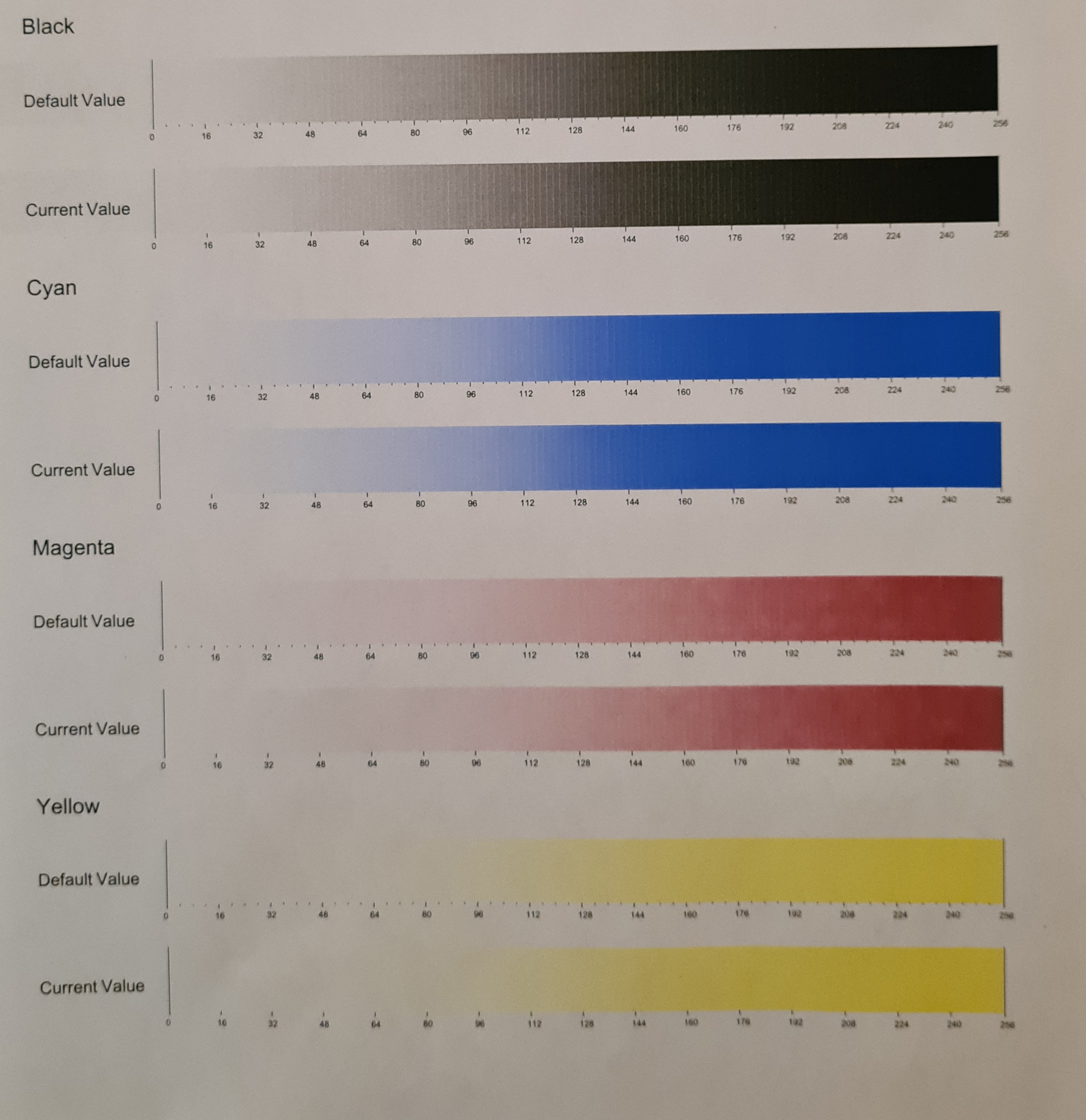

The future technology of these printers also provides stability of colors. While the decorated porcelain goes through an kiln at 1400-2200°F older pigments would naturally change dramatically through the intense heat. But now the pigments are very stable and do not change at all through the firing process.

This cutting edge, digital printing process is stable firing up to temperatures of 2200°F allow the image to sink into the pre-glazed porcelain providing permanency whether from scratching or sun damage.

These upgrades allow any image to be permanently embedded into any porcelain decoration at full color and high resolution.

Wanna Get Into Porcelain & Ceramic Printing Yourself?

We limit this opportunity to folks with the capital and time to learn a new cutting edge printing technology.

Packages start at $10,000 USD and $20,000 USD

Call us 416 410 8797 and ask to speak to someone in printer sales.

Helpful to know:

- Art and more specifically Graphic Arts

- Do you know about kilns or have access to one?

- Want to learn something truly unique and have the patience and more patience to learn it.

- Have room for a printer and kiln. Kilns can in most cases legally go into garage. You can check out your own area and many kilns can be small to huge.

- This is not a part time job, this will keep you as busy as you want to be.

- No competition in many areas, or very little competition and we talk about this in the training you will be getting.

Call us 416 410 8797 ext. 1 and ask to speak to someone in "Printer Sales".